- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

S32750 Super Duplex Steel Blind Flanges

We are a reliable manufacturer of S32750 Super Duplex Steel Blind Flanges in China. Our products are of high quality, and we are committed to providing the best after-sale service and timely delivery to our customers. Whether you are a new or existing customer, we welcome you to continue working with us to create a better future. You can trust us to provide you with the S32750 Super Duplex Steel Blind Flanges you need for your projects.

Send Inquiry

Zhejiang Chengyuan S32750 Super Duplex Steel Blind Flanges Introduction

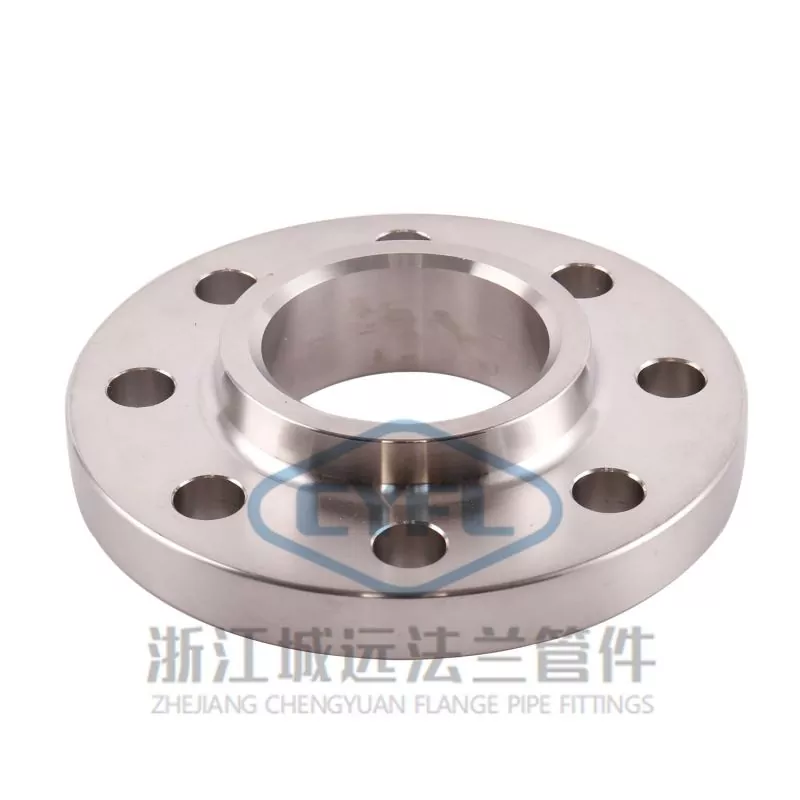

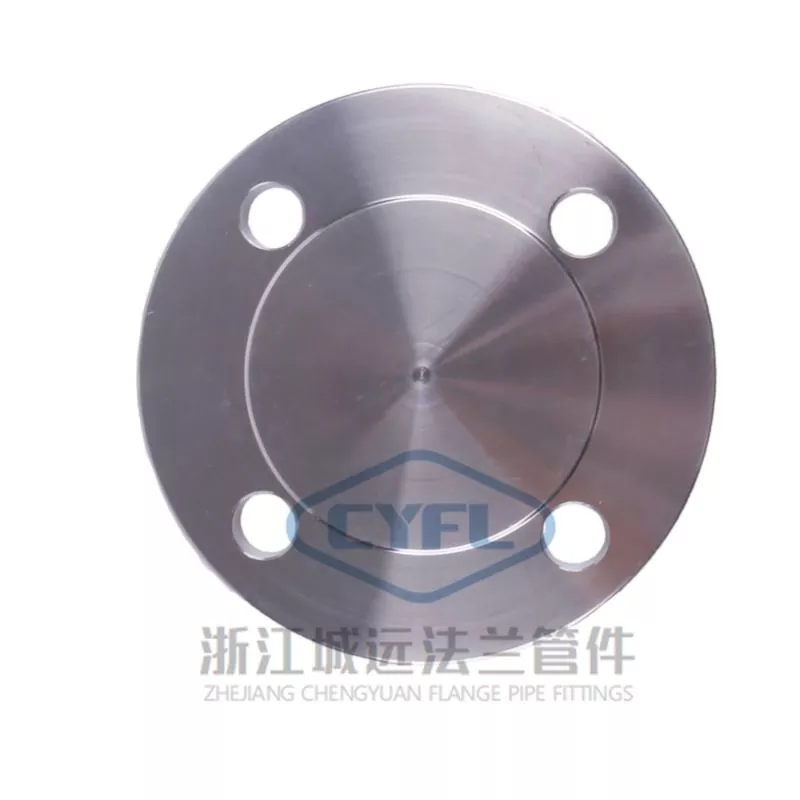

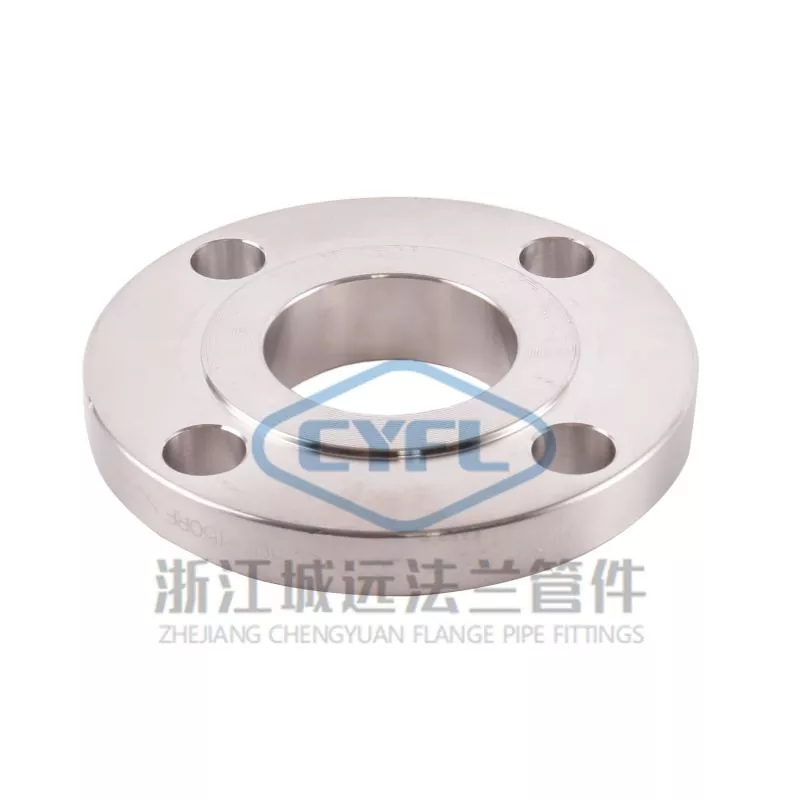

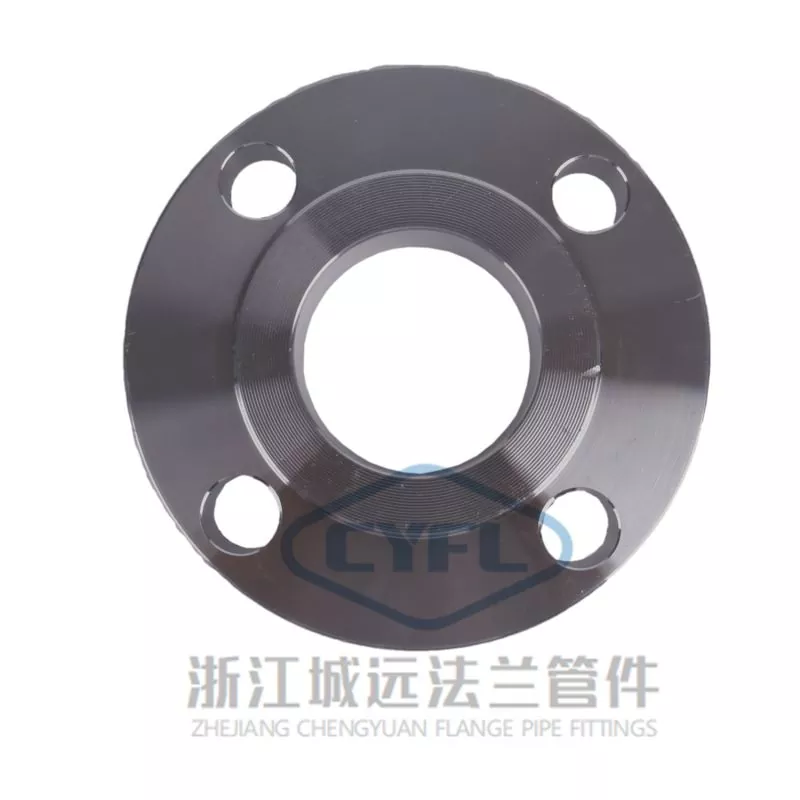

S32750 Super Duplex Steel Blind Flanges are pipeline connectors that possess exceptional mechanical strength, corrosion resistance, and wear resistance. They are constructed using S32750 super duplex stainless steel, a material renowned for its ability to withstand extreme environments. These flanges feature a flat blind plate that is utilized for pipeline blocking purposes. They can control fluid flow by obstructing the pipeline or temporarily shutting down and maintaining the system. S32750 Super Duplex Steel Blind Flanges are extensively used in a range of industries, including chemical processing, construction, water treatment, oil and gas production, shipbuilding, power generation, pharmaceuticals, and food manufacturing.

Zhejiang Chengyuan S32750 Super Duplex Steel Blind Flanges Parameter (Specification)

S32750 Super Duplex Steel has the following chemical composition:

- Carbon (C): maximum 0.030%

- Manganese (Mn): maximum 1.20%

- Silicon (Si): maximum 0.80%

- Phosphorus (P): maximum 0.035%

- Sulfur (S): maximum 0.020%

- Chromium (Cr): 24.00-26.00%

- Molybdenum (Mo): 3.00-5.00%

- Nickel (Ni): 6.00-8.00%

- Nitrogen (N): 0.24-0.32%

- Iron (Fe): minimum 58.095%

Zhejiang Chengyuan S32750 Super Duplex Steel Blind Flanges Feature And Application

The S32750 Super Duplex Steel Blind Flanges have a wide range of applications due to their excellent overall performance. They are commonly used in basic projects such as chemical industry, construction, water supply, drainage, oil, light and heavy industry, refrigeration, health, plumbing, fire protection, electric power, aerospace, and shipbuilding.

The technical parameters for their application include nominal pressure of seal Pn, Mpa (bar), and the type of surface, which can be concave and convex surface (MFM), tenon and groove surface (TG), or full plane (FF). The applicable size ranges from DN300 to DN3000, depending on the type of surface.

Zhejiang Chengyuan S32750 Super Duplex Steel Blind Flanges Details

Zhejiang Chengyuan S32750 Super Duplex Steel Blind Flanges PROCESS flow