- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

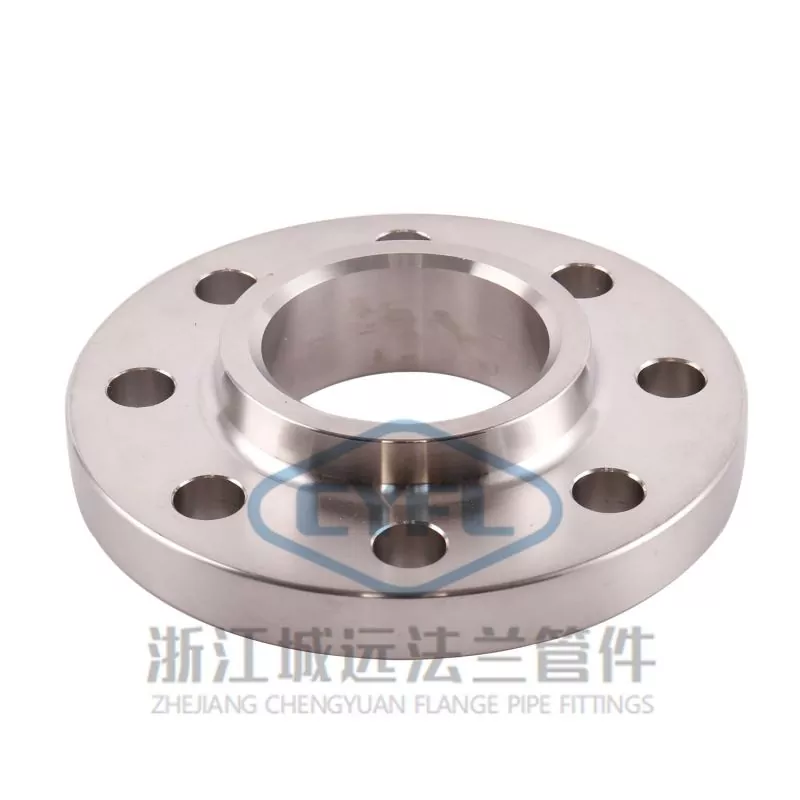

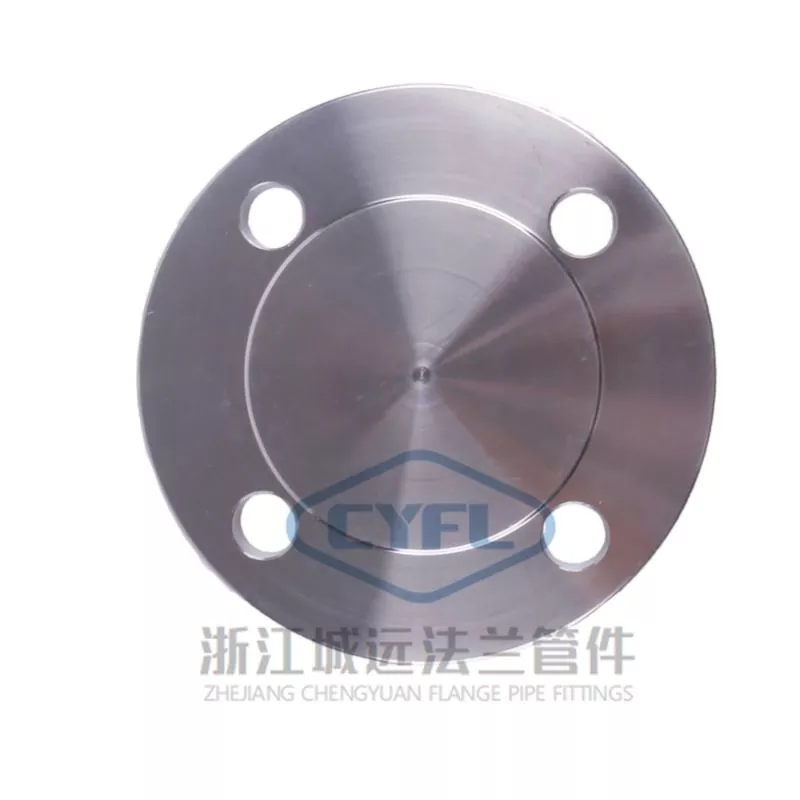

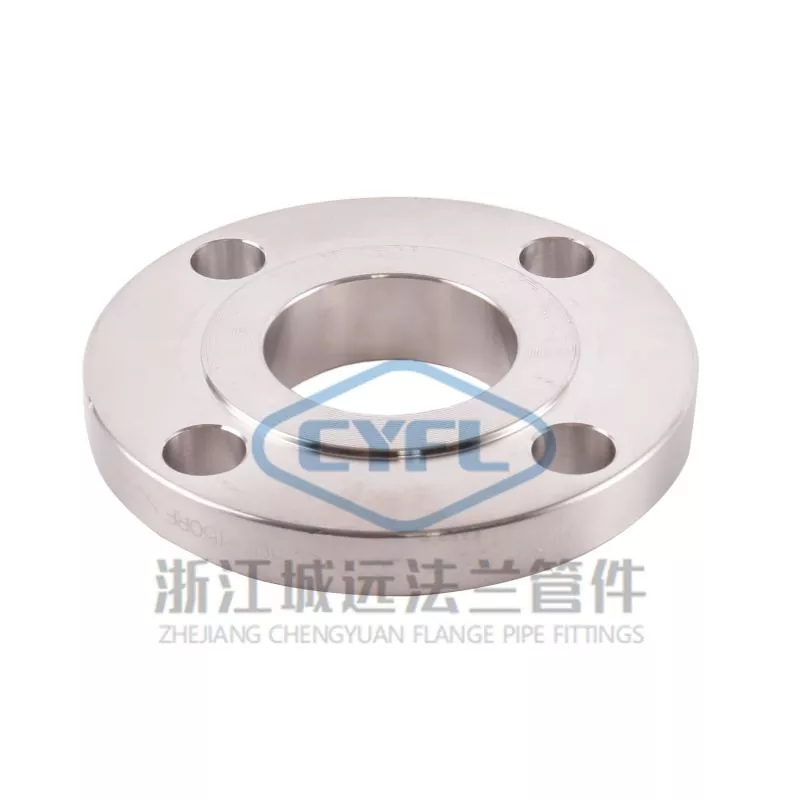

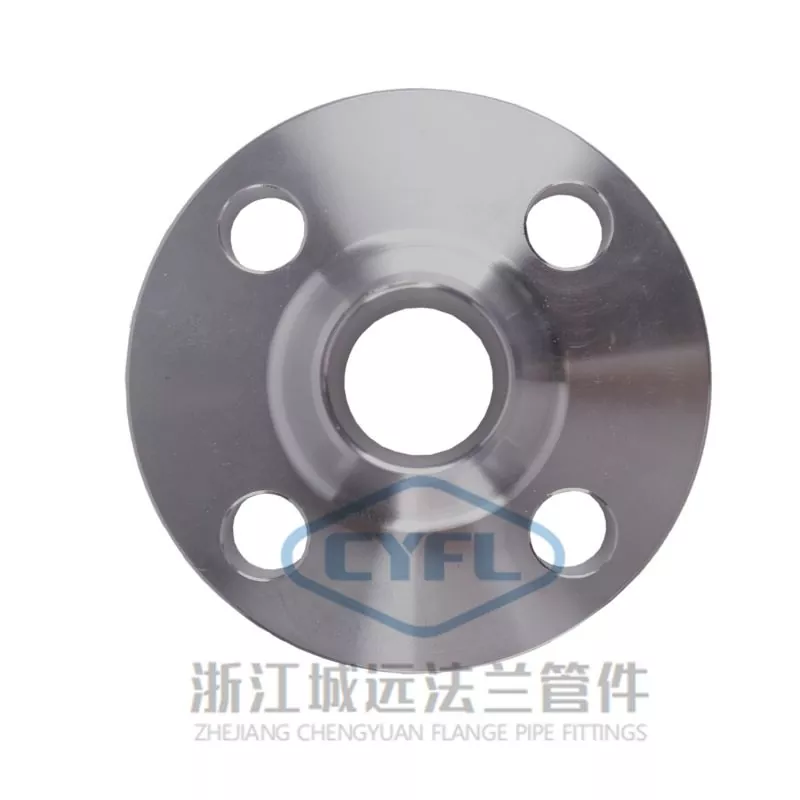

S32750 Super Duplex Steel Slip on Flange

You can trust us to provide you with customized S32750 Super Duplex Steel Slip on Flanges that meet your specific requirements. We are looking forward to collaborating with you and addressing any questions you may have. Our goal is to keep you updated with the latest news and developments related to S32750 Super Duplex Steel Slip on Flanges, as the market for these products is constantly evolving. To stay up-to-date, we suggest bookmarking our website and visiting it regularly for the most recent updates.

Send Inquiry

Zhejiang Chengyuan S32750 Super Duplex Steel Slip on Flange Introduction

S32750 Super Duplex Steel Slip on Flange is a type of pipe flange that is designed to slip over the end of a pipe and then be welded in place. It is made from S32750 Super Duplex Steel, which is a high-performance alloy known for its excellent corrosion resistance, high strength, and good weldability. The slip-on flange is easy to install and provides a strong, leak-proof connection between pipes or other equipment. It is commonly used in a wide range of industries, including oil and gas, chemical, and power generation.

Zhejiang Chengyuan S32750 Super Duplex Steel Slip on Flange Parameter (Specification)

Here are the parameters/specifications for S32750 Super Duplex Steel Slip on Flange:

Material: S32750 Super Duplex Steel

Size: 1/2"-80" (DN10-DN2000)

Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#

Standard: ASME B16.5, ASME B16.47, MSS SP 44, API, BS, DIN, JIS

Face Type: RF, FF, RTJ

Surface Treatment: Anti-rust Oil, Black Paint, Yellow Paint, Zinc Plated, Cold and Hot Dip Galvanized

Packing: Wooden Case, Pallet, or as per customer's requirement

Zhejiang Chengyuan S32750 Super Duplex Steel Slip on Flange Feature And Application

Flange connection, also known as flange joint, is a detachable assembly sealing structure composed of flanges, gaskets, and bolts. It is commonly used in pipeline and equipment connections. Flanges have holes through which bolts are inserted to connect two flanges together. A gasket is placed between the two flanges to provide a tight seal. There are several types of flanges, including threaded, welding, and clamp types. Flanges are typically used in pairs and selected based on the required pressure rating and thickness, with appropriate bolts and gaskets. Welding flanges are suitable for high-pressure applications, while threaded flanges are used for low-pressure applications. Different pressure ratings require different thicknesses and bolt sizes for secure connections.

Zhejiang Chengyuan S32750 Super Duplex Steel Slip on Flange Details

Zhejiang Chengyuan S32750 Super Duplex Steel Slip on Flange PROCESS flow