- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

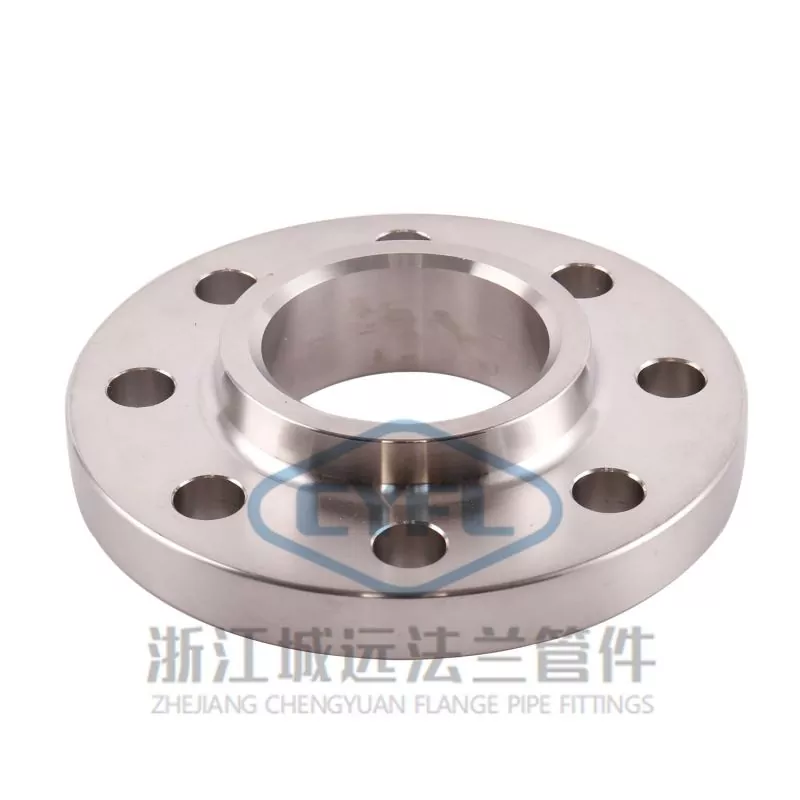

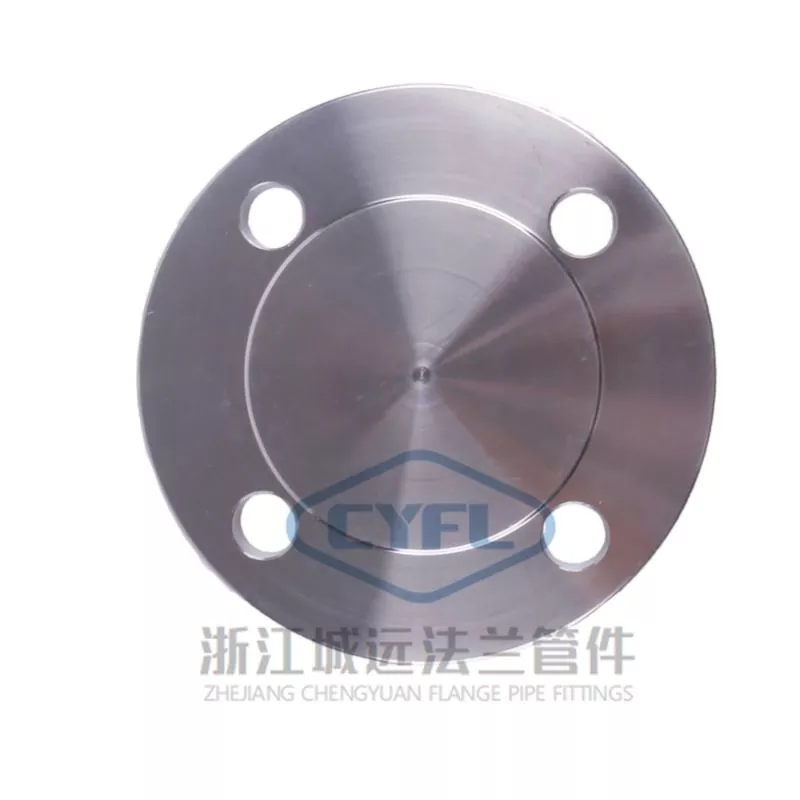

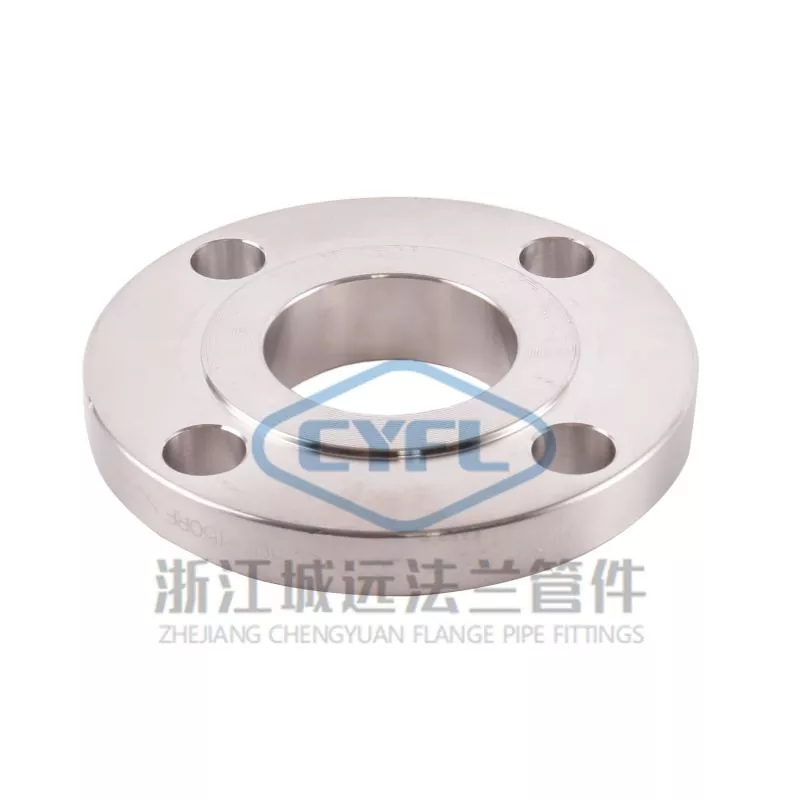

S32750 Super Duplex Steel Threaded Flanges

We provide the latest news and updates on S32750 Super Duplex Steel Threaded Flanges to keep you informed about the market trends and changes. It is important to stay up-to-date in this evolving market, and we suggest bookmarking our website to receive regular updates and information. Our goal is to provide valuable insights and knowledge to help you better understand and expand your business in the S32750 Super Duplex Steel Threaded Flanges market.

Send Inquiry

Zhejiang Chengyuan S32750 Super Duplex Steel Threaded Flanges Introduction

A threaded flange is a type of flange that is connected to a pipe by threading. It can be designed as a loose type flange, which means that no welding is required and the additional torque on the cylinder or pipe when the flange is deformed is very small. Although the flange thickness is larger and the cost is higher, it is suitable for high-pressure pipelines.

To connect the threaded flange with a pipe, the inner hole of the flange is processed into a pipe thread. This type of flange does not require welding, making it convenient for installation and maintenance. It is often used in pipelines where welding is not allowed on site. When choosing between alloy steel flanges and threaded flanges, consider the welding performance and strength of the alloy steel. If the steel is difficult to weld or has poor welding performance, threaded flanges may be a better option.

However, threaded flanges should not be used when the temperature of the pipe changes rapidly or when the temperature is higher than 260℃ and lower than -45℃. This can cause leakage and other issues. It is important to choose the right type of flange for the specific application to ensure safe and efficient operation.

Zhejiang Chengyuan S32750 Super Duplex Steel Threaded Flanges Parameter (Specification)

Threaded flanges can be made from a variety of materials, including stainless steel (A182 F304/304L/316/316L/321/347, Duplex F51/F53/F44/F55/F60/F61), alloy steel (ASTM A694/A694M F42/F46/F52/F56/F60/F70, A182 F5/F9/F11/F22), and carbon steel (ASTM A105, ST37.2, A350 LF1/LF2/LF3, API 6A AISI 4130). They conform to various international standards such as ASTM/ASME/ANSI B16.5, B16.47, ASME/ANSI B16.48, JIS/KS (5K, 10K, 16K, 20K), DIN2633, DIN2634, DIN2635, EN1092, BS4504, AWWA C206, and API 6A. The flanges come in sizes ranging from 1/2" to 120" (DN15-DN3000) and pressure ratings from Class150 to Class2500, JIS 5k-30k, and DIN 6bar-40bar. The face types are FF, RF, and RTJ, and they can be treated with surface galvanization, antirust coating, epoxy & FBE coating, and protected with plastic caps. The flanges are packed in pallets or wooden cases (fumigation-free) and are accompanied by ISO9001, PED, and EN10204 3.1 MTC certifications. Customized drawings are also welcomed.

Zhejiang Chengyuan S32750 Super Duplex Steel Threaded Flanges Feature And Application

S32750 Super Duplex Steel Threaded Flanges are a type of non-welded flange used for connecting pipes with matching threads. These flanges are made of S32750 super duplex steel, which is a high-performance alloy that offers excellent corrosion resistance and mechanical strength.

Some of the features of S32750 Super Duplex Steel Threaded Flanges include:

- High strength and toughness

- Excellent corrosion resistance in a variety of harsh environments, including seawater, acidic and alkaline solutions, and chloride-containing environments

- Good weldability and workability

- Resistance to stress corrosion cracking and pitting corrosion

These flanges are commonly used in applications where welding is not allowed or not practical, such as in high-pressure pipelines, oil and gas industry, chemical processing, and seawater applications.

The advantages of S32750 Super Duplex Steel Threaded Flanges include:

- Easy installation and maintenance

- No need for welding, reducing the risk of leaks and weld defects

- High strength and corrosion resistance, making them suitable for demanding applications

- Can be used in a wide range of temperatures and environments

Overall, S32750 Super Duplex Steel Threaded Flanges offer a reliable and efficient solution for connecting pipes in various industrial applications.

Zhejiang Chengyuan S32750 Super Duplex Steel Threaded Flanges Details

Zhejiang Chengyuan S32750 Super Duplex Steel Threaded Flanges PROCESS flow