- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

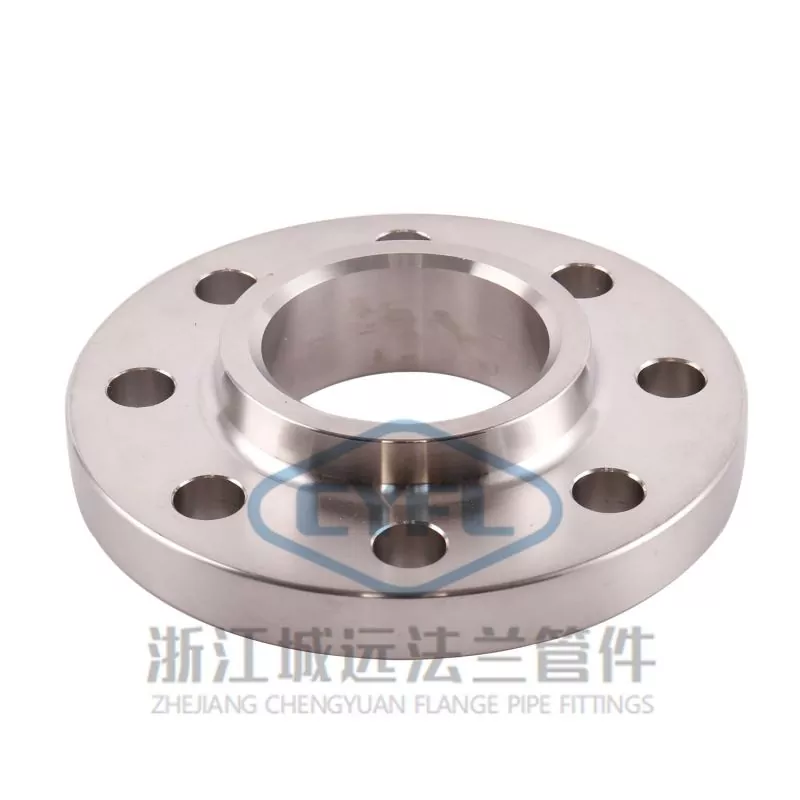

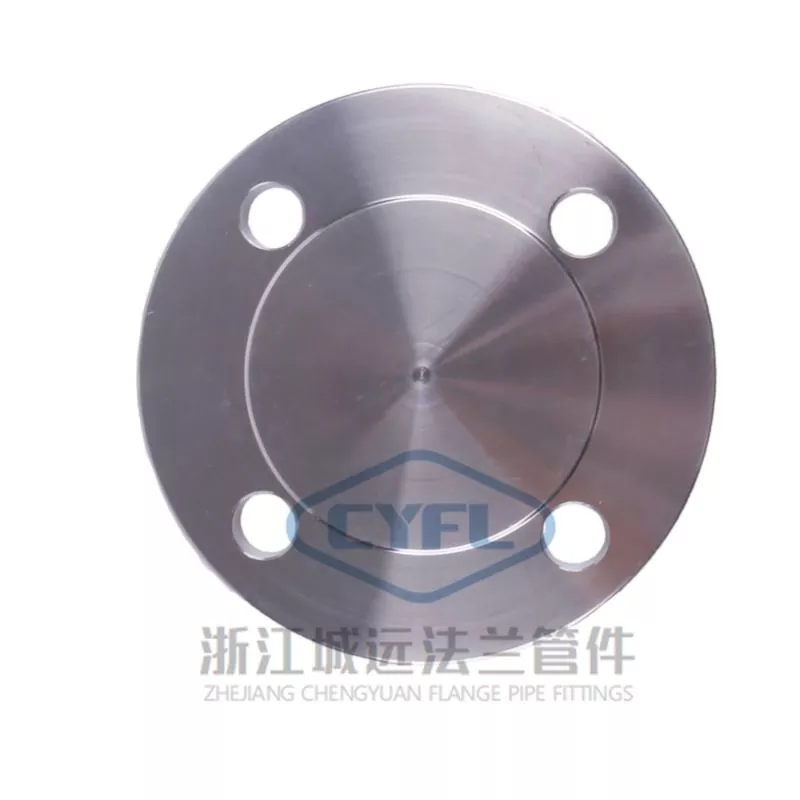

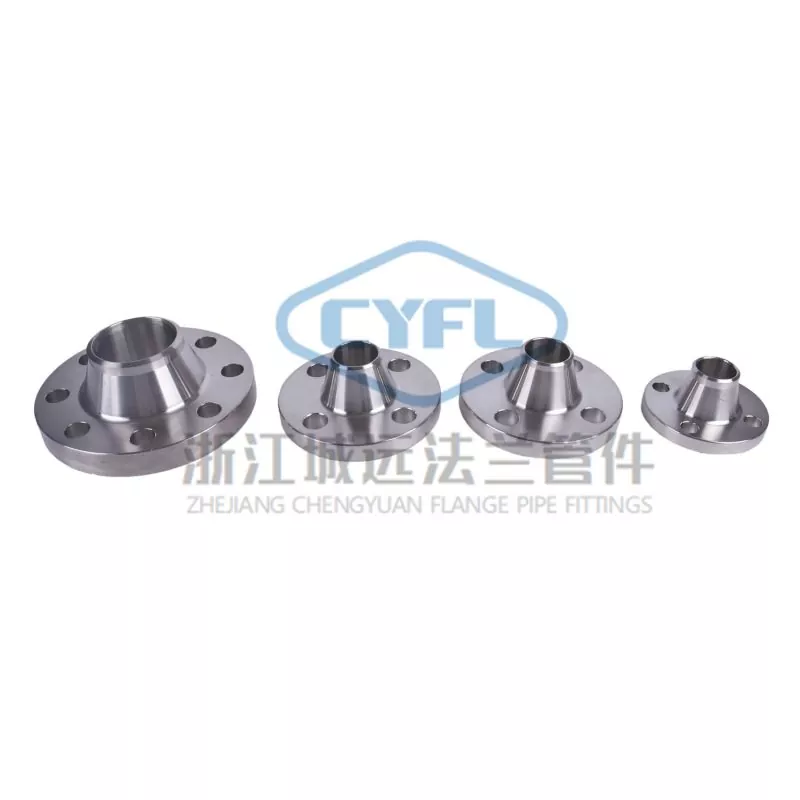

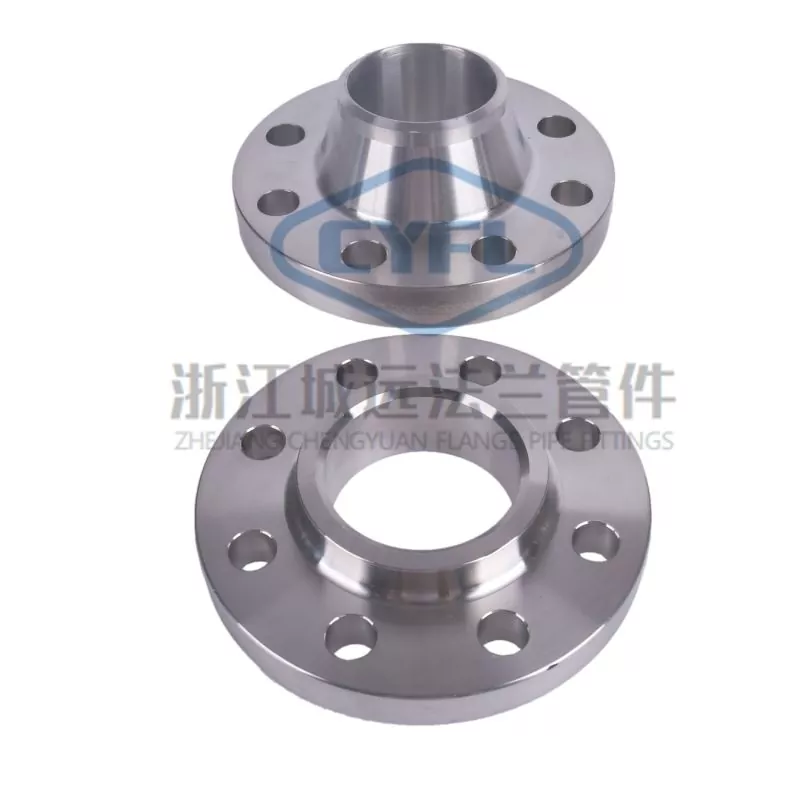

S32760 Super Duplex Steel Socket weld Flanges

We invite you to visit our factory and purchase our popular, cost-effective, and top-notch S32760 Super Duplex Steel Socket Weld Flanges. We are eager to collaborate with you and guarantee the customization of your order. Please feel free to contact us for further information, and we will respond promptly to your inquiries.

Send Inquiry

Zhejiang Chengyuan S32760 Super Duplex Steel Socket weld Flanges Introduction

S32760 Super Duplex Steel Socket Weld Flanges serve as connectors for pipes and valves within pipeline systems. They are constructed from high-strength S32760 super duplex steel, which boasts exceptional resistance to corrosion. Given their durability and anti-corrosive properties, these flanges are extensively employed across various industries, including chemical processing, oil and gas, marine engineering, and shipbuilding. By being welded onto the pipe end, Socket Weld Flanges establish an airtight seal, effectively preventing any leakage of fluids.

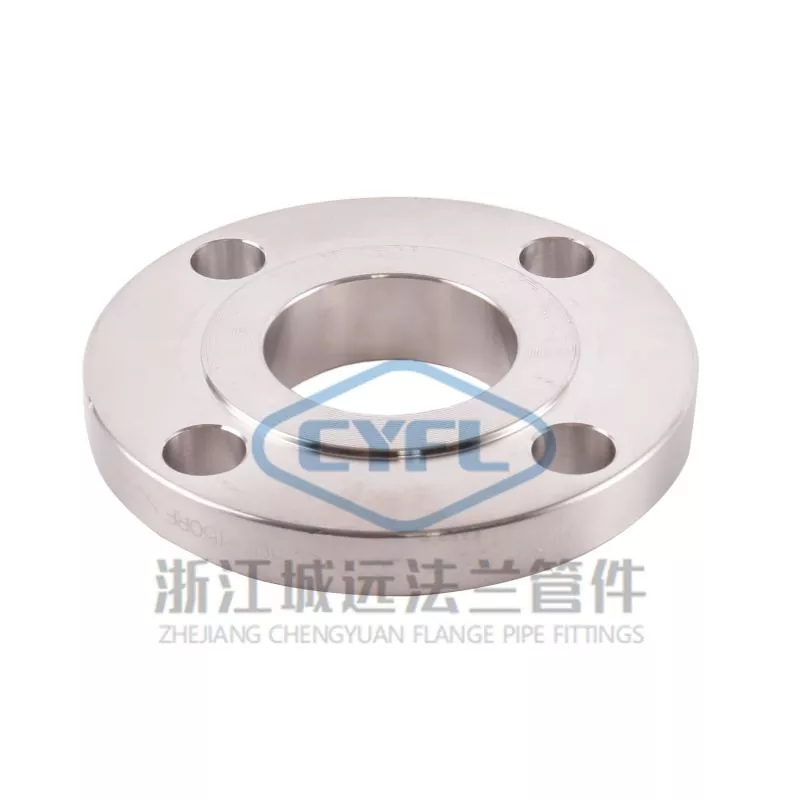

Zhejiang Chengyuan S32760 Super Duplex Steel Socket weld Flanges Parameter (Specification)

This is a Schedule 40 Socket Weld Flange with a nominal pipe size of 1 inch and an outside diameter of 4 1/4 inches. The overall length of the flange is 11/16 inches. The material grade is 304/304L stainless steel, and the maximum operating pressure is 275 psi with a maximum steam pressure of 150 psi. The flange has four bolt holes with a diameter of 5/8 inches, and a bolt circle diameter of 3 1/8 inches. The connection surface is raised face, and the fitting connection type is flanged x socket weld. The flange thickness is 1/2 inch, and it belongs to Class 150.

Zhejiang Chengyuan S32760 Super Duplex Steel Socket weld Flanges Feature And Application

A threaded flange is a type of flange that has its holes machined to create pipe threads, allowing it to be connected to pipes without welding. The connection is made by threading the flange hole and matching it with the pipe's corresponding threads. The threaded flange can have various types of threads, including tapered, cylindrical, and conical threads. It is commonly used in applications such as air conditioning water systems and engineering construction, where the pressure is low and welding is not suitable.

Threaded flanges are not high-pressure flanges and have a limited range of applicable pressure, usually ranging from 0.6 to 4.0 MPa, with diameters ranging from DN10 to DN150. They are not suitable for use in hazardous environments, due to their structural characteristics. The sealing surface of a threaded flange is either a full plane or protruding surface.

In China, threaded flanges are typically only applicable to the English pipe series, and the outer diameter of the steel pipe matched with a DN65 flange should be 73mm, while the outer diameter of steel pipe for a DN125 flange should be 141.3mm. When adopting a 60 degree conical pipe thread, the outer diameter of steel pipe for DN150 flange should be 165.1mm.

Threaded flanges are a type of non-welded flange, providing the advantages of convenient site installation, easy maintenance, and avoiding welding-related issues. They are typically neck flanges, and flat-welded neck flanges and socket-welded flanges of other sizes are the same, except for the differences in the inside of the flanges.

Zhejiang Chengyuan S32760 Super Duplex Steel Socket weld Flanges Details

Zhejiang Chengyuan S32760 Super Duplex Steel Socket weld Flanges PROCESS flow