- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

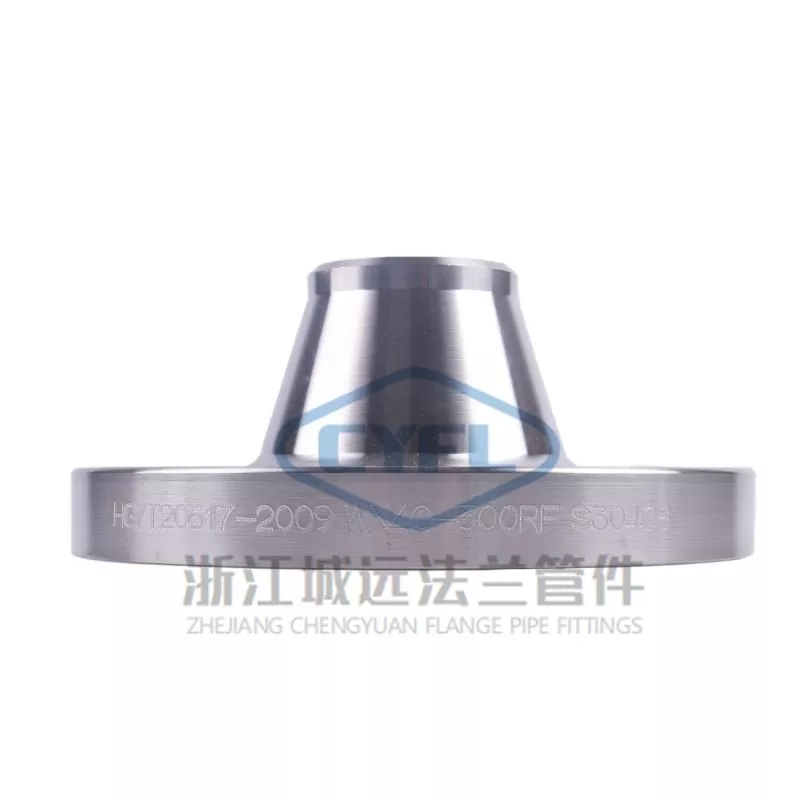

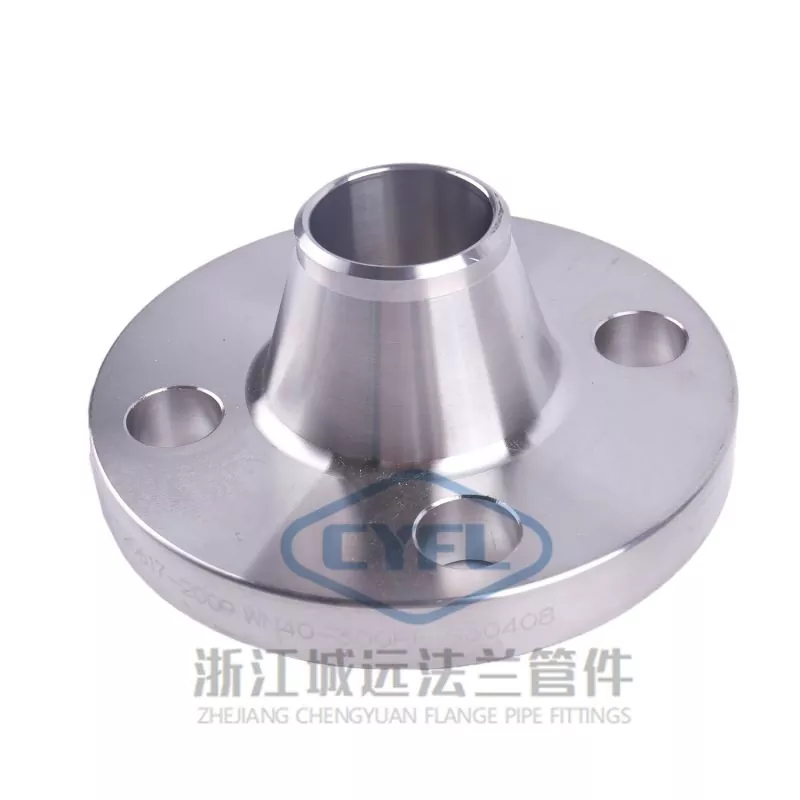

S32760 Super Duplex Steel Weld Neck Flanges

This news update pertains to S32760 Super Duplex Steel Weld Neck Flanges and provides the latest information on this product to help you stay informed and expand your market for S32760 Super Duplex Steel Weld Neck Flanges. As the market for this product continues to evolve and change, we suggest bookmarking our website to receive regular updates and stay ahead of the competition. We are committed to keeping you informed of the latest developments in the S32760 Super Duplex Steel Weld Neck Flanges market.

Send Inquiry

Zhejiang Chengyuan S32760 Super Duplex Steel Weld Neck Flanges Introduction

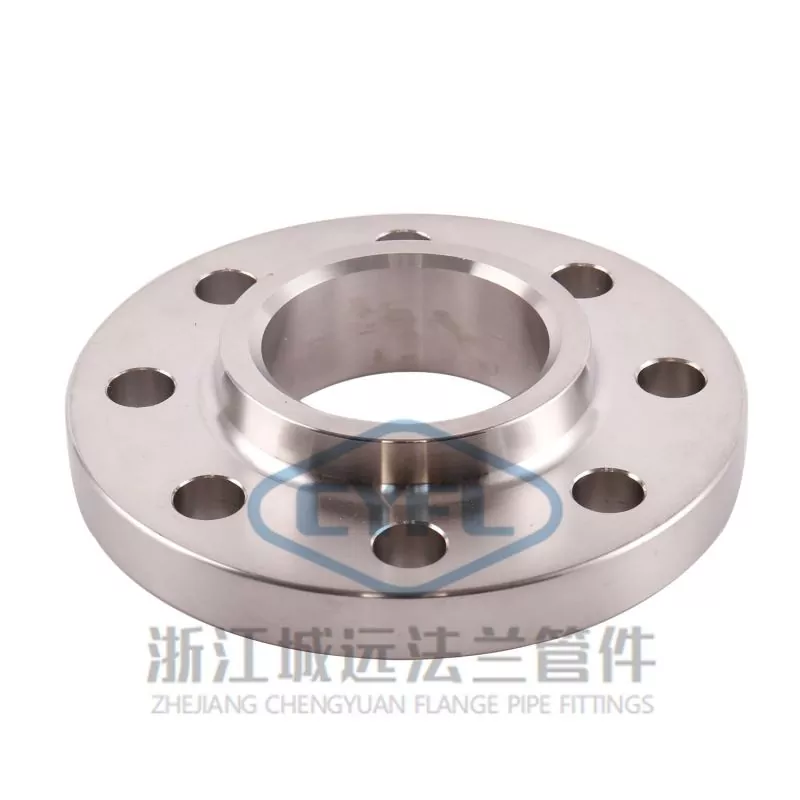

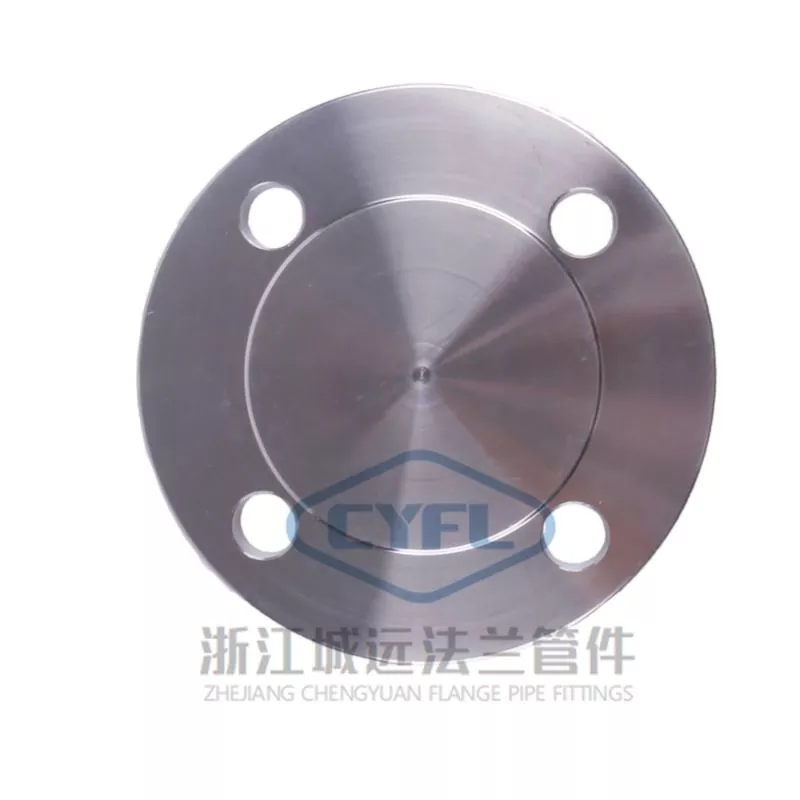

There are several types of flanges used in pipe connections, including sliding flanges, lap flanges, and socket welded flanges.

Sliding flanges have a lower hub and are welded inside and outside to prevent leakage. They are bored to match slightly larger OD pipes and are a cost-effective option for many users. However, the final installation cost may not be lower due to the less added neck flange welds.

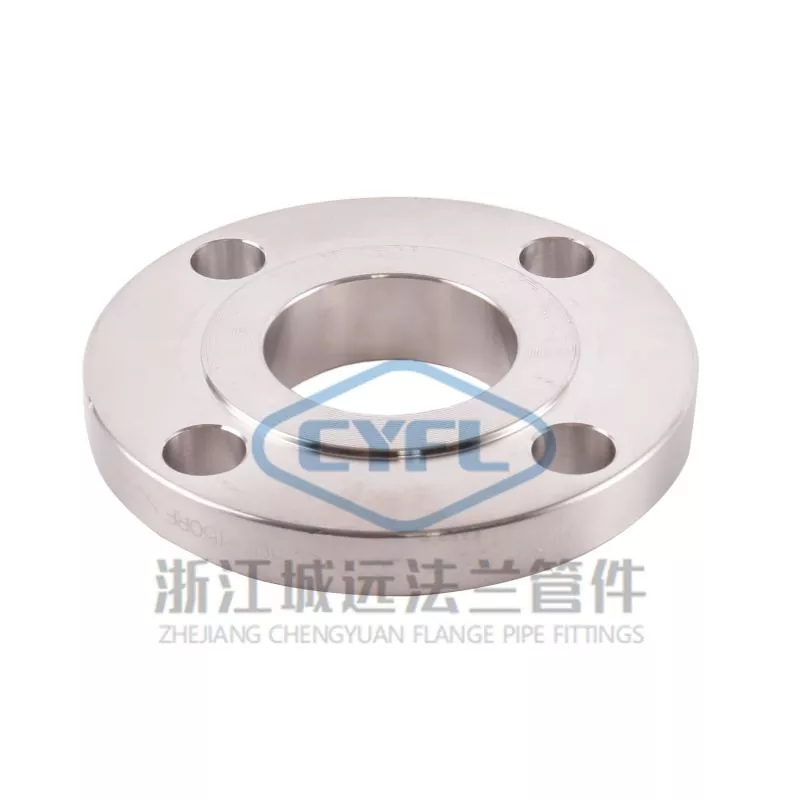

Lap flanges are similar to sliding flanges, except they have a radius between the hole and the flange race. This is necessary to accommodate the lap stub end. Lap flanges and lap stubs end mating together are used to assemble the system.

Socket welded flanges are similar to sliding flanges, but have a hole and a reverse hole size. The counter hole is matched with the pipe, and the diameter of the smaller hole is the same as the ID of the pipe. There is a built-in hole at the bottom as a shoulder sleeve designed for piping, which eliminates any flow limitation.

Zhejiang Chengyuan S32760 Super Duplex Steel Weld Neck Flanges Parameter (Specification)

Here are the parameters/specifications for S32760 Super Duplex Steel Weld Neck Flanges:

- Material: S32760 super duplex stainless steel

- Size range: 1/2" to 48" (DN15 to DN1200)

- Pressure rating: Class 150 to Class 2500 (PN6 to PN400)

- Facing: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Standards: ASME B16.5, ASME B16.47, MSS SP-44, API 605, AWWA C207, BS 3293, DIN 2632-2638, EN 1092-1

- Applications: Used in high-pressure and high-temperature pipeline systems in industries such as oil, gas, and chemical processing.

Zhejiang Chengyuan S32760 Super Duplex Steel Weld Neck Flanges Feature And Application

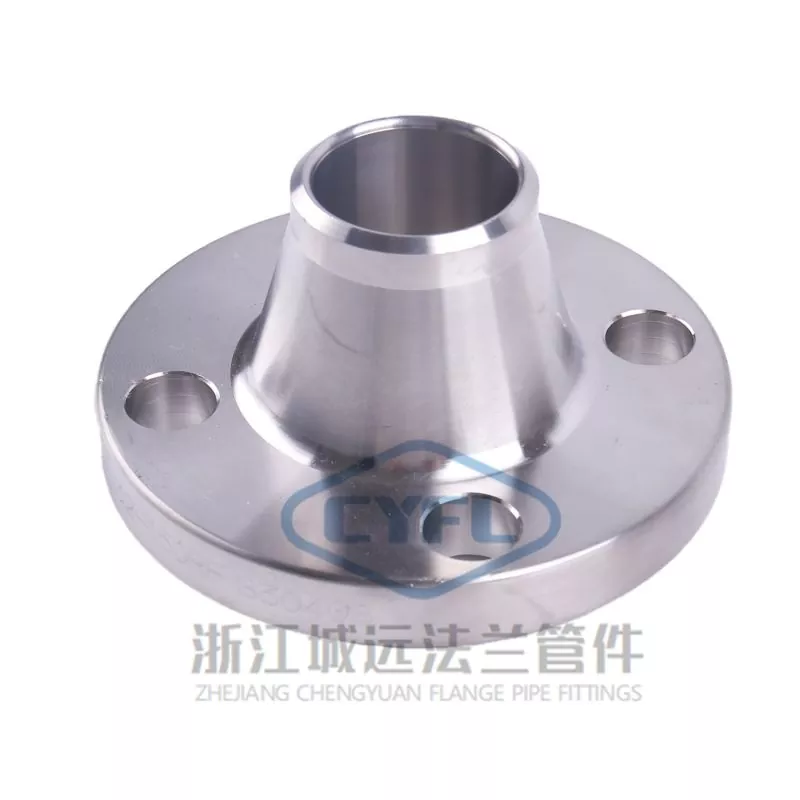

S32760 Super Duplex Steel Weld Neck Flanges are pipeline connectors made from S32760 super duplex stainless steel. They are typically designed with a neck and a flat end, where the neck is welded to one end of the pipeline and the flat end is connected to another pipeline that is also welded. Due to the design of this connector, it can provide excellent strength and sealing performance, making it ideal for use in pipeline systems operating under high pressure and high temperature conditions, such as in the petroleum, natural gas, and chemical industries.

Zhejiang Chengyuan S32760 Super Duplex Steel Weld Neck Flanges Details

Zhejiang Chengyuan S32760 Super Duplex Steel Weld Neck Flanges PROCESS flow