- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

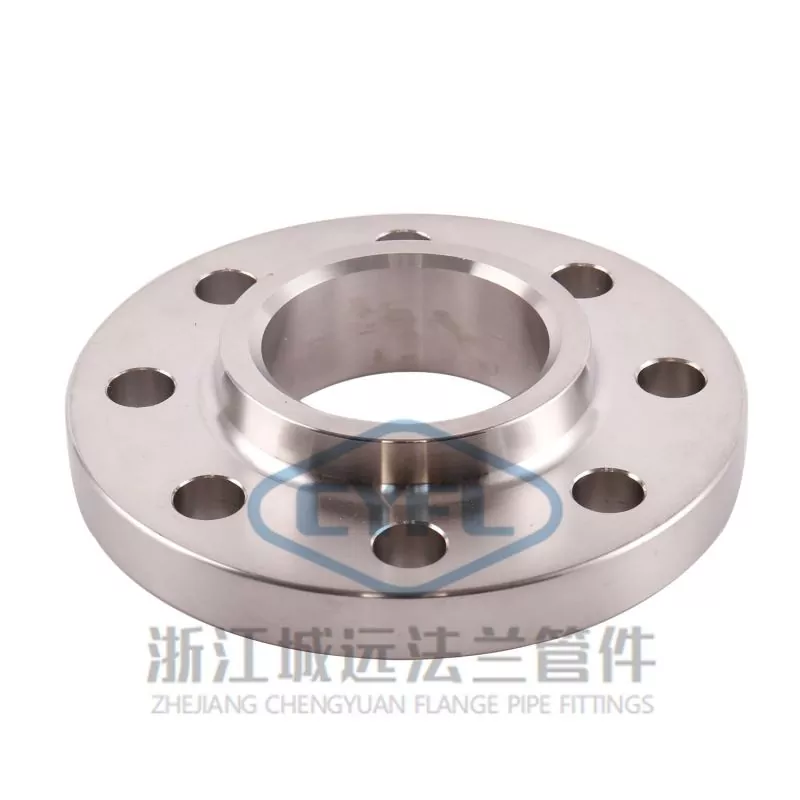

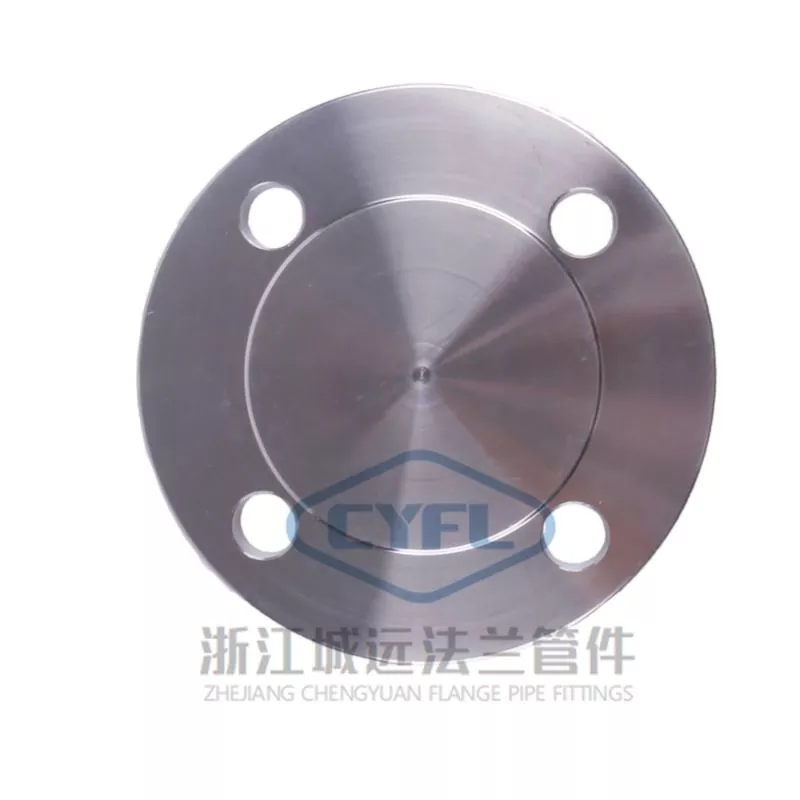

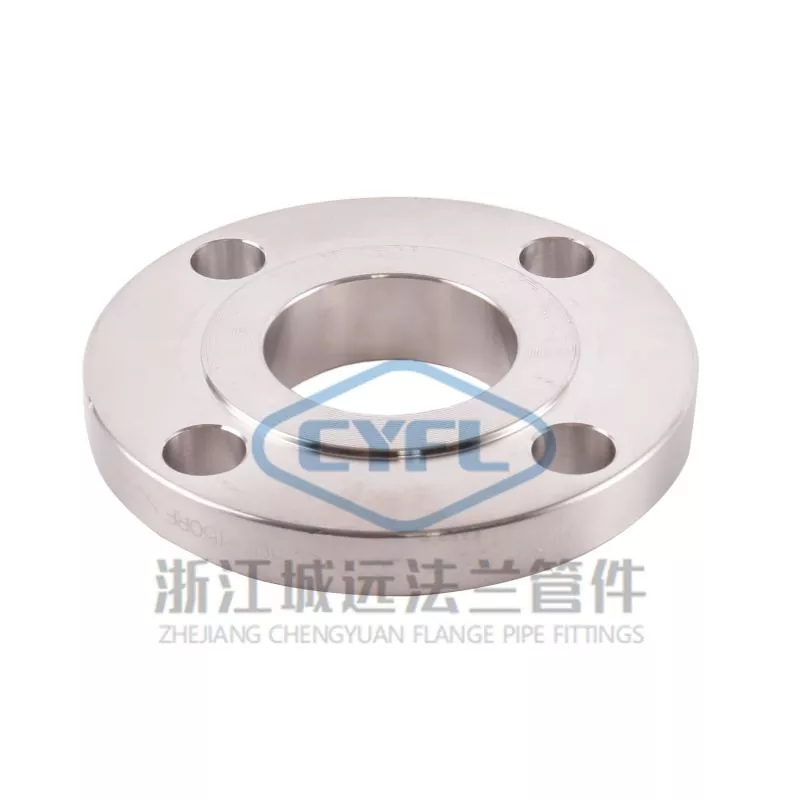

3 Piece Stainless Ball Valve

As a trusted manufacturer of 3 piece stainless ball valves in China, we guarantee the quality of our products and offer a reliable after-sale service to ensure customer satisfaction. You can confidently purchase our 3 piece stainless ball valves from our factory, and we will provide timely delivery to meet your needs.

Send Inquiry

Zhejiang Chengyuan 3 piece stainless ball valve Introduction

A 3 piece stainless ball valve is a type of ball valve that consists of three valve bodies, typically made of stainless steel. Ball valves are used in many different fluid control and regulation applications, including liquids, gases, and steam. Its design makes it easy to maintain and clean, and it has the ability for quick shutdown and startup. Three-piece ball valves are typically easy to disassemble and assemble because the valve bodies can be separated, making maintenance more convenient.

Zhejiang Chengyuan 3 piece stainless ball valve PROCESS FLOW

Installation of hard-sealed valve:

1) Remove the protective covers on both flange ends and fully open the valve before flushing it.

2) Prior to installation, the entire assembly should be tested according to the specified signal (electricity or gas) to ensure its service performance is not affected by transportation vibrations. Once the test has been passed, the valve can be installed online (wiring according to the circuit diagram of the electric actuator).

3) Prior to connecting the valve to the pipe, flush and clean the pipe of any remaining impurities that may damage the seat and ball.

4) When installing, avoid using the actuator part of the valve as the lifting point to prevent damage to the actuator and accessories.

5) The valve should be installed in the horizontal or vertical direction of the pipeline.

6) Ensure that the pipeline near the installation point is not drooping or bearing external force. Pipeline supports can be used to eliminate any deviation in the pipeline.

7) After connecting the valve to the pipe, use the specified torque to cross-lock the flange connecting bolts.

Zhejiang Chengyuan 3 piece stainless ball valve Feature And Application

Ball valves are versatile devices that can be used in a variety of fluid control and regulation applications. They are particularly suitable for situations where there is a need for strict sealing performance, mud, wear, shrinkage channel, rapid opening and closing action, high pressure cut-off, low noise, cavitation and gasification phenomenon, a small amount of leakage to the atmosphere, small operating torque, and small fluid resistance in pipeline systems.

Ball valves can also be used in low-pressure cut-off, corrosive media pipeline systems, and low-temperature (cryogenic) devices and piping systems. In addition, ball valves can be used in situations where fire and fire prevention are a concern, particularly in the petroleum, chemical, and metallurgical industries, where flammable and explosive media are present.

When selecting a ball valve, it is important to consider the materials used for the valve seat sealing ring and the structure and performance of the valve. Plastic valve seat sealing rings are commonly used and can be deformed to compensate for ball manufacturing accuracy and surface roughness, ensuring reliable sealing performance. However, if fire and fire prevention are a concern, metal to metal sealing ball valves should be considered.

Overall, ball valves are an excellent choice for a wide range of fluid control and regulation applications and can provide reliable and efficient performance in many different environments.