- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Three Piece Stainless Ball Valve

Stay up-to-date with the latest developments in the three piece stainless ball valve market by regularly visiting our website. We provide updated information and news on the latest trends, innovations, and changes in the industry, helping you better understand and expand your knowledge of three piece stainless ball valves. As the market for these valves continues to evolve and change, our website is your go-to source for the most current and relevant news and information. We encourage you to bookmark our website and check back frequently for the latest updates.

Send Inquiry

Zhejiang Chengyuan Three piece stainless ball valve Introduction

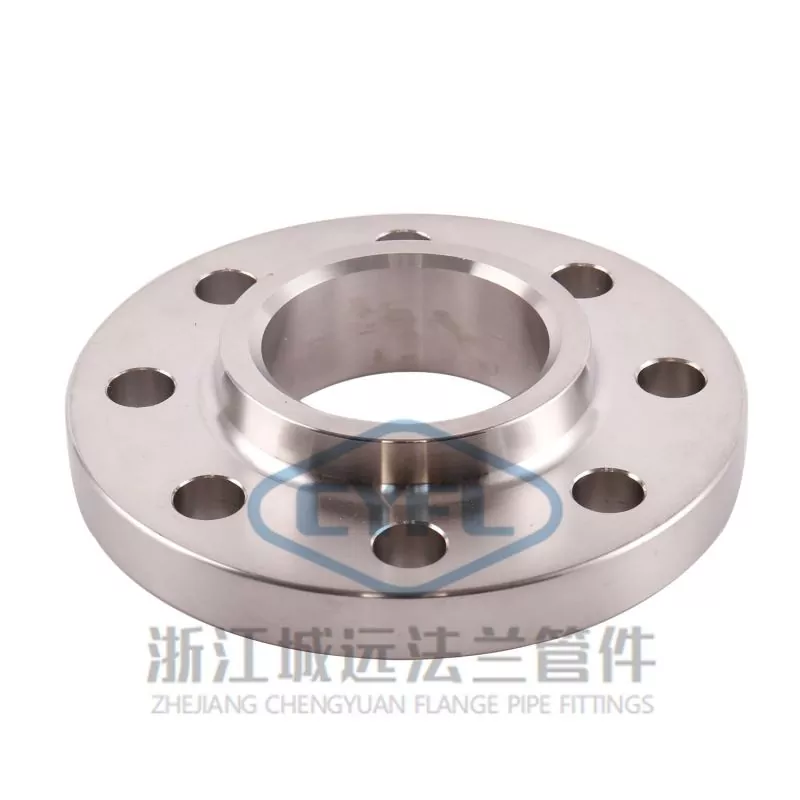

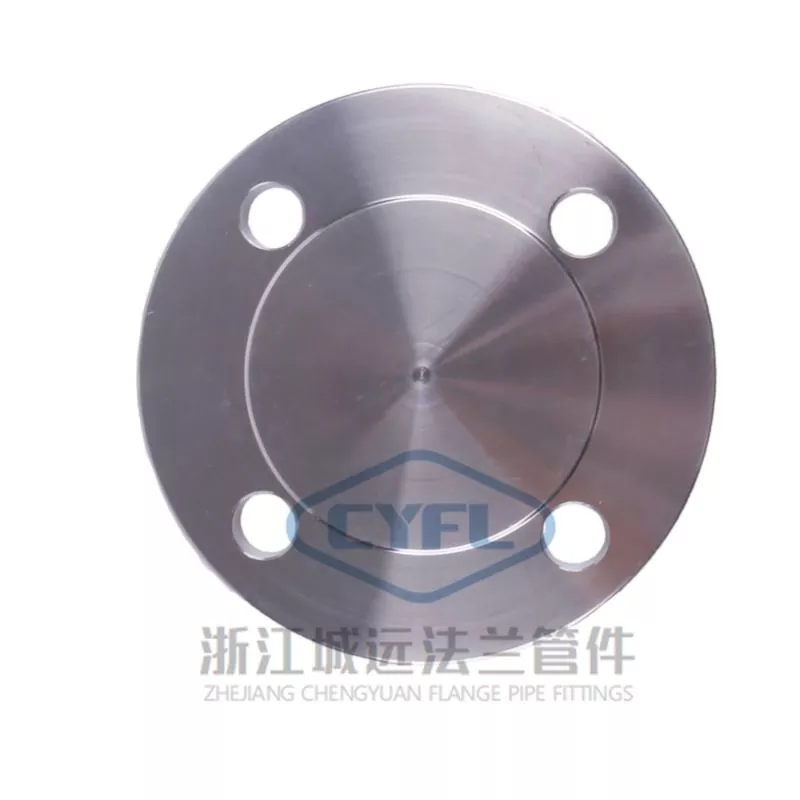

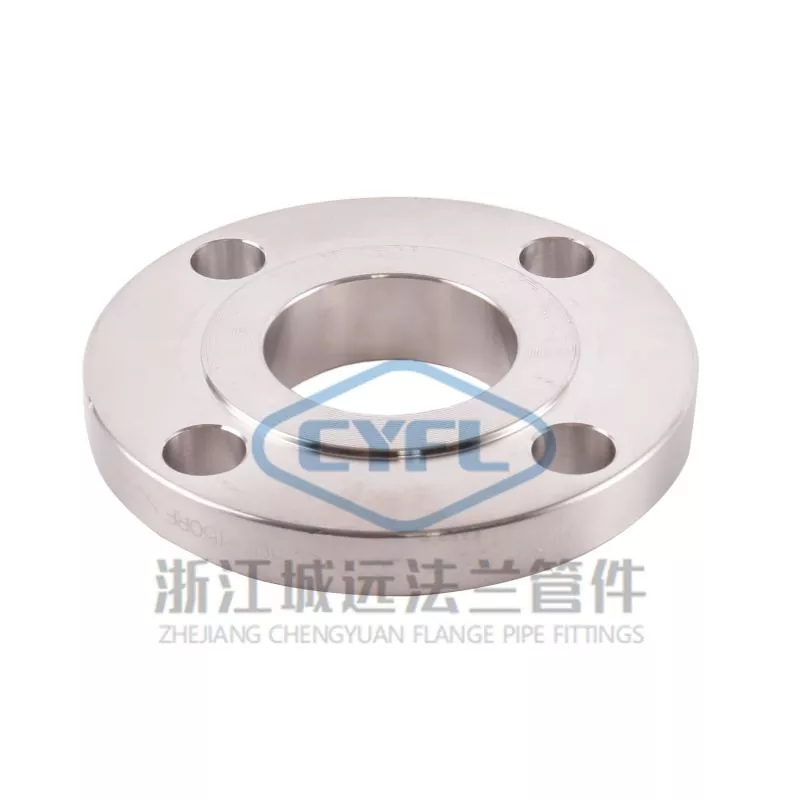

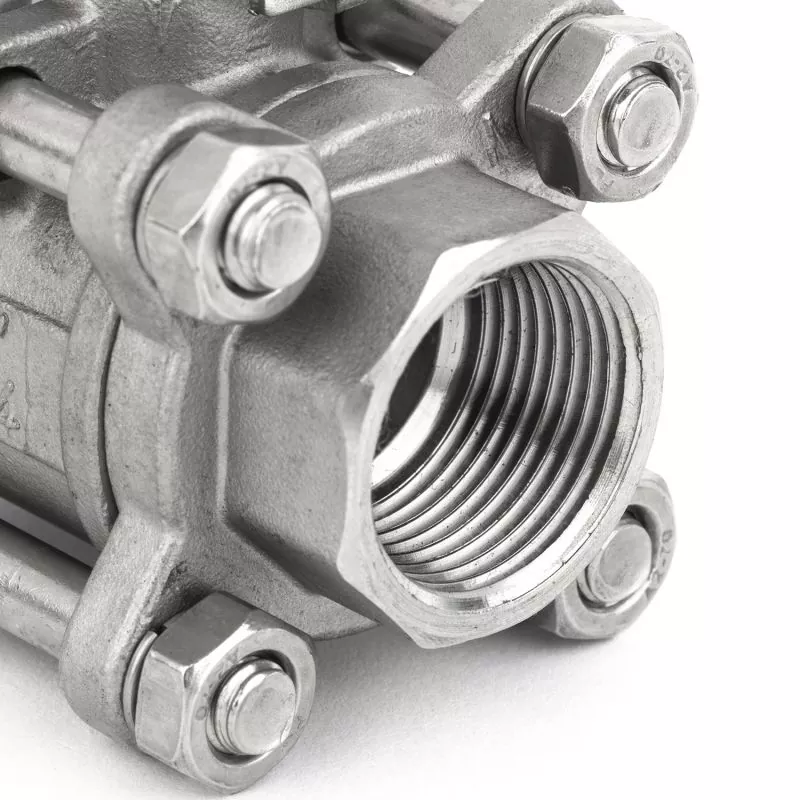

A three-piece stainless ball valve is a type of ball valve that consists of three valve bodies and is typically made of stainless steel. It is suitable for many different fluid control and regulation applications, including liquids, gases, and steam. Its design makes it easy to maintain and clean, and it has the ability to quickly open and close. Three-piece ball valves are typically easy to disassemble and assemble because the valve bodies can be separated, making maintenance more convenient.

Zhejiang Chengyuan Three piece stainless ball valve PROCESS FLOW

Here are some guidelines for the operation and maintenance of the ball valve:

1. Before operation, ensure that the pipeline and valve are thoroughly flushed.

2. To operate the valve, rotate the valve stem according to the input signal size of the actuator. The valve shuts off when the valve rotates 1/4 turn (90°) forward, and opens when it is rotated 1/4 turn (90°) in reverse.

3. The position of the valve can be determined by observing the direction indicating arrow on the actuator. When the arrow is parallel to the pipeline, the valve is open, and when it is perpendicular, the valve is closed.

4. The service life and maintenance-free period of the valve depend on factors such as normal working conditions, a harmonious temperature/pressure ratio, and reasonable corrosion data.

5. Before performing maintenance, relieve the line pressure and keep the valve in the open position, disconnect the power or air supply, and detach the actuator from the bracket.

6. Make sure to remove the pressure from the upper and downstream pipelines of the ball valve before disassembling it.

7. When disassembling and reassembling the valve, take care not to damage the sealing surface of the parts, especially the non-metallic parts. Use special tools when removing the O-ring.

Zhejiang Chengyuan Three piece stainless ball valve Details

8. When assembling the valve, tighten the bolts on the flanges symmetrically, step by step, and evenly.

9. Use a cleaning agent that is compatible with the rubber parts, plastic parts, metal parts, and working media (such as gas) in the ball valve. For metal parts, gasoline (GB484-89) can be used to clean them, while non-metal parts can be cleaned with pure water or alcohol.

10. Non-metallic parts should be removed from the cleaning agent immediately after cleaning, to prevent damage or contamination.

11. Before assembly, new parts should also be cleaned.

12. During assembly, ensure that no impurities, debris, or pollution enter the inner cavity or stay on the surface of the parts.

13. If there is micro leakage at the packing, the stem nut must be locked again, but not too tightly (usually 1/4 to 1 turn).